Subsea

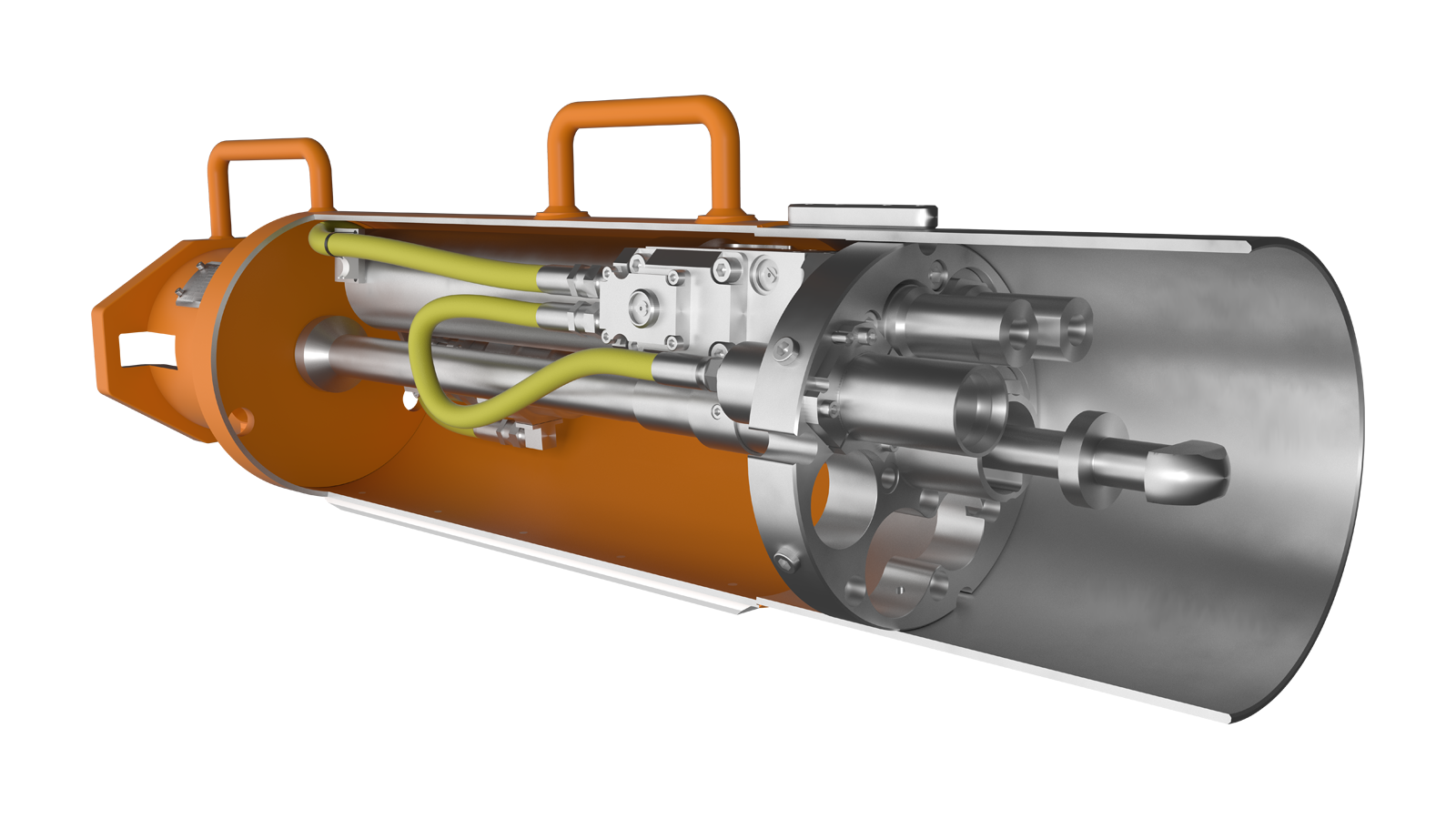

Our subsea chemical injection metering valves and back pressure regulators meet high operating standards and are built to withstand harsh conditions.

-

View

ViewSubsea Chemical Injection Metering Valves (CIMV)

Our subsea chemical injection metering valve (CIMV) models feature SkoFlo’s industry-leading pressure-independent technology for reliable, stable, and accurate chemical injection.

-

View

ViewSubsea Back Pressure Regulators (BPR)

Our subsea back pressure regulators (BPR) are anti-siphoning, self-regulating devices that help to prevent the uncontrolled delivery of chemicals into production wells. The subsea BPR requires no electronics, making it ideal for brownfield solutions to combat chemical siphoning.

Benefits of Using SkoFlo’s Subsea Technology

Our subsea pressure independent valves are operationally rated to 15,000 psi. SkoFlo's simple yet elegant pressure independent regulator provides the industry's most stable and accurate chemical injection with nearly instantaneous reaction time to maintain accurate injection in response to system changes.

-

Pressure-Independent

Upstream and downstream pressure fluctuations, which are countered by a spring force, create a net force on the patented pressure-balanced piston to maintain constant flow.

-

Accurate Flow Delivery

Our pressure‐balanced piston provides instantaneous control at different injection points from a common line that is more tolerant to debris and fluid filming. No pneumatic or electric power sources are required for this control.